How To Make An Optimal Oil Analysis Step By Step

Posted on 05/25/20 in: Technical Knowledge | | General Industry | Author: Mike Holloway

American Society for Testing and Materials (ASTM) sets the standards for most industrial oil tests. In addition, other standards are set by American Petroleum Institute (API) for engine oils, National Lubricating Grease Institute (NLGI) for greases, American Gear Manufacturers Association (AGMA) for gears, and there are also international standards set by the International Standards Organization (ISO) and Deutscher Industrie Normen (DIN). Most of the following are based on ASTM standards.

It is important to take samples from an area that is a representative of the system if possible. In a circulating system, this should be taken while the system is operating at normal loads, speeds and temperatures. Whenever possible, it should be drawn from the most turbulent part of the system.

It is wise to test a sample of unused oil to use it as a reference to see how the oil in the system changes with time. Samples should be labeled clearly. It is a good idea to identify the sample on the bottle itself as well as on accompanying paperwork. Labels should include:

- Oil type (manufacturer and product), Equipment ID code

- Equipment type, date

- Person responsible, Company name, Location

- Test program or tests required

There is a certain amount of error expected in oil analysis tests. ASTM generally puts repeatability and reproducibility limits on each standard. Repeatability refers to test results generated by the same person at the same lab.

Reproducibility gives the range of results expected if different people at different laboratories ran the same test on the same sample. The following are tests performed on lubricating oil:

Appearance and Color

Detect changes that have taken place in the oil including contamination with other products, water (often evidenced by haziness/cloudiness when in excess of 200 PPM), and oxidation (darkening of the product).

The product should be clear and bright with no visible water or particulate. A comparison to new unused product is useful for evaluating color. The test is conducted using a Colorimeter to visually inspect the samples and determine the color.

The fluid sample is compared to color standards according to the ASTM Color Scale. The results are reported from 0.5 – 8.0. The higher the number, the darker the fluid. Highly oxidized turbine oils will become dark when compared to new oil. Also, lube mixing and other contamination may cause a color change.

Carbon Residue - measures the amount of carbon residue remaining in an oil after the oil has been subjected to extreme heating in the absence of air. Test results are reported as Conradson Carbon and Ramsbottom Carbon.

Cloud Point - the temperature at which paraffin wax, or other compounds present in the oil will begin to crystallize or separate from solution when the oil is chilled under prescribed conditions.

Coking Test - determining the tendency of oils to form solid decomposition products when in contact with surfaces at elevated temperatures. The Panel Coker test measures the residue on hot panels that have been coated with oil.

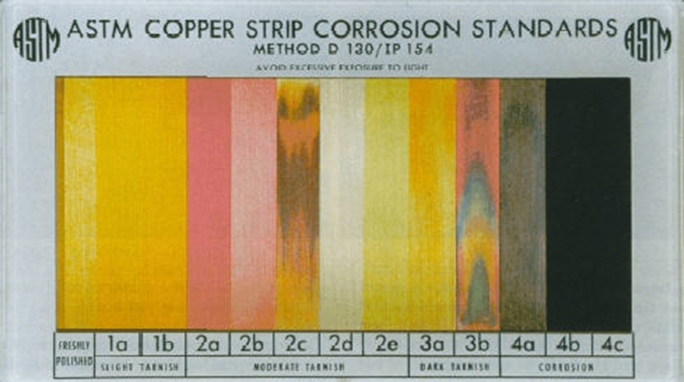

Copper Corrosion - measures corrosion on a copper strip when it is immersed in a lubricant under standard conditions. Results are reported on a scale from 1a (slight tarnish) to 4c (jet- black corrosion).

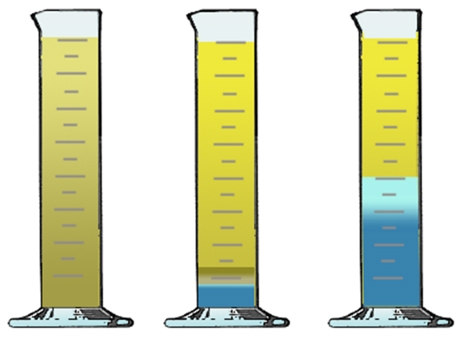

Demulsibility - Indicates the ability of an oil to separate from water under static conditions. A test result of 40/40/0 would mean clear oil and water, with no emulsion.

The Dynamic Demulsibility test measures the ability of an oil to separate from water under actual circulating conditions. The test requires 40 ml Water, 40 ml Oil into cylinder, agitated, then allowed to settle. Timed at intervals to determine the ability to shed water, <3 ml cuff (emulsion) expected.

Density - reported as specific gravity or API gravity. Specific Gravity is the ratio of the weight in air of a given volume of material at a stated temperature to the weight in the air of an equal volume of distilled water at the same temperature. A hydrometer is an instrument that measures the specific gravity of a liquid.

API Gravity - an arbitrary scale (chosen by the American Petroleum Institute) in which the specific gravity of pure water is taken as 10. Liquids lighter than water have values greater than 10 and liquids heavier than water have values less than 10° API. It is calculated from the specific gravity of a petroleum oil.

Dielectric Strength - measure of oil’s ability to resist conducting electricity. The test is run by immersing two electrodes in a bath of oil and subjecting them to increasing voltage until there is an arc. This and other tests suggested by IEEE and ANSI are used to determine the suitability of continued use of transformer oils.

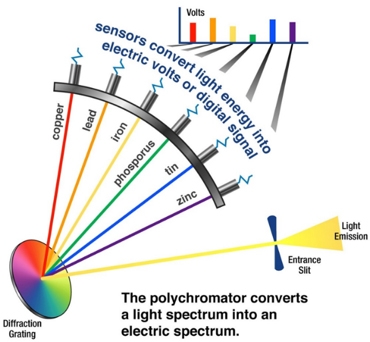

Metals – measures in the part per million for wear metals, contaminants, and organometallic oil additives. Use of emission spectrometry measures the level of 23 metals, but only if they are less than 10 microns in size. It is used for measuring common water, additive and contaminant metals. The emission technique relates to light given off by an element whereas the absorption technique relates the absorbency upon excitation.

The following are metals that are commonly measured by spectrometry, and their possible sources.

- Aluminum - piston, shell bearing, bushing, thrust washer, block, head, blower, crankcase paint, grease additive

- Barium - additive (high-TBN detergent)

- Boron- coolant additive, oil additive (dispersant)

- Calcium - additive (high-TBN detergent), seawater

- Chromium - plating, liner, ring, shaft, gear, coolant additive

- Copper - bearing, bushing, thrust washer, piston insert, gear, axial hydraulic piston assembly, seal, copper in an engine oil shortly after initial fill may come from an oil cooler

- Iron - piston, ring, cylinder, gear, block, head, cam, shaft, roller bearing, shell bearing back, and seal

- Lead - bearing, shaft, thrust plating, piston insert, wet clutch, gas additive, off-the-shelf- supplement (OTSS)

- Magnesium - additive (high-TBN detergent), seawater, some gas turbine metallurgy

- Molybdenum - ring plating, additive (anti-wear), off-the-shelf-supplement (OTSS), Nickel steel alloy, “heavy” fuel contaminant, valve seat

- Phosphorus - additive (anti-wear), synthetic phosphate ester lube, phosphoric acid (plant environment)

- Potassium - coolant additive

- Silicon - dirt, antifoam oil additive, coolant additive, seal, synthetic lube, wet clutch

- Silver- EMD wrist pin bushing, turbo bearing, bearing plating or alloy, silver solder

- Sodium - coolant additive, oil additive, seawater

- Tin - bearing, bushing, piston, plating, alloy

- Titanium - gas turbine bearing, hub, blade, ‘white’ lead, paint

- Vanadium- steel alloy, ‘heavy’ fuel contaminant

- Zinc- additive, galvanized metals/plumbing, brass component

Flash Point - the lowest temperature at which oil gives off sufficient vapors so that the vapors will ignite when a small flame is periodically passed over the surface. This is a measure of the temperature required to produce an ignitable vapor-air mixture above the liquid when exposed to an open flame. It helps determine if oil is contaminated with a lower viscosity fluid.

For example, low flash point of engine oil may indicate fuel dilution. Three commonly used flash point tests are ASTM D 92 Cleveland Open Cup, ASTM D 93, Pensky-Martens Closed Cup, ASTM D 56 Tag Closed Cup.

Closed cup tests are normally used for substances with a low flash point such as solvents and fuels. Fuel dilution can be tested by using gas chromatography. This method detects fuel and other volatile hydrocarbons that can contaminate lubricants.

Some of the causes of fuel dilution in a diesel engine include extended idling or defective fuel injectors, pumps, fuel lines and timing. If fuel is indicated in gasoline engines, check for problems with fuel injectors, carburetor, choke, ignition or poor warm-up.

Fire Point - the lowest temperature at which oil ignites and continues to burn for at least five seconds. Fire point ranges from 10°F to 70°F higher than the flashpoint of a product.

Foam Test - measures the volume of oil foam generated by blowing air through a sample of oil in a graduated cylinder at specified temperatures. The air inlet tube is fitted with a 1-inch diameter spherical glass diffuser stone of fused crystalline alumina grain at the bottom of the cylinder. The air pressure is maintained at a constant rate for a specified blowing time (usually 5 minutes). Sequence I is run at 75°F, Sequence II at 200°F, and Sequence III after the sample has cooled to 75°F again.

The level of foam is measured immediately after each sequence, and then after a 10-minute settling time. The two numbers are reported as foam tendency/stability. A test result of 150/20 would mean that there were 150 mls of foam immediately after blowing, and 20 mls after it had settled for 10 minutes.

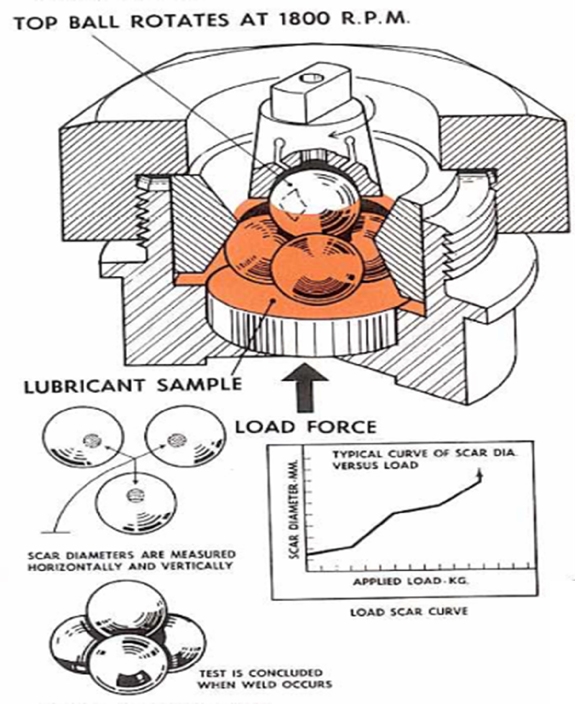

4-Ball Wear / Weld - four ½ inch steel balls are arranged with one ball atop three others. The three lower balls are clamped together, and the fourth sits on top like a pyramid and is rotated under increasing load.

In the 4-Ball wear test, after a measured time and load, the scars on the balls are measured. In the EP test, load is applied until the balls weld together. That point is recorded as the weld point.

Load Wear Index is a proportion of the weight and scar diameters when load is applied just before the weld point. It indicates the level of EP performance in oil. A high level of EP would be 50 to 75, and moderate EP would be 35 to 45.

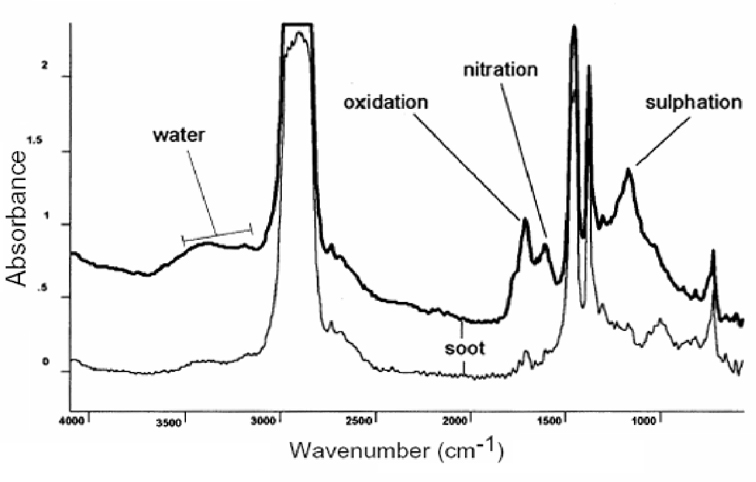

Fourier Transform Infrared Spectroscopy (FTIR) - identifies organic functional groups by measuring their infrared absorption at various wavelengths. Results are expressed in absorbance units per centimeter and range from 1 to 100. It is useful in measuring oxidation, nitration, and glycol contamination. A good new oil reference sample is needed to get good used oil results.

Also, a special unit is used to measure soot. It can measure water, hydrocarbons, oxidation products, nitration products, and glycol. Fuel soot is run in a special infrared analysis unit designed specifically for fuel soot. It shows the amount of carbon produced by combustion.

Fuel soot is a contributing factor in viscosity increase. For diesel engines, elevated fuel soot can indicate faulty injectors and/or inefficient engine operation.

Acid Number (AN) - expressed as the amount of potassium hydroxide (KOH) required to neutralize the acid in one gram of oil. An oil’s acid number is a measure of the concentration of strong and weak acids in the sample. New oils have a total acid number; oils with more additives usually have a higher number.

An increase in TAN, as the oil ages, indicates an increase in weak acids, which are caused by oxidation. High TAN can reflect over-extended drain intervals, excessively high system temperatures or oil oxidation.

Base Number (BN) - the measure of oil’s reserve alkalinity to neutralize acids occurring in engine oil. It is obtained by titration with hydrochloric acid, but is expressed in mg of KOH equivalent. TBN reflects the life left in the lubricant. Very low TBN indicates over-extended drain intervals or the use of oil with insufficient TBN for the sulfur content of the fuel.

Rotating Pressure Vessel Oxidation Test (RPVOT ) - indicates the level of the oxidation inhibitor content remaining in used oil. Its test results are recorded as the number of minutes it takes for a test sample to reach an oxygen pressure drop of 25 psig. RBOT is a useful trend analysis tool for monitoring the remaining life of turbine oils and paper machine oils.

Pour Point - the lowest temperature at which the oil will pour or flow under prescribed conditions when it is chilled without disturbance at a fixed rate. To determine pour point, a sample of oil is cooled in a test jar under specified conditions: the temperature is observed in increments of –5°F until no movement is apparent on the surface of the oil when the test jar is held in a horizontal position for 5 seconds. This temperature is recorded as the solid point.

Rust Prevention - indicates the ability of lubricating oil to prevent corrosion during the lubrication of ferrous parts in the presence of water. A steel test rod is placed in the beaker of oil and water at 140F for 24 hours and the results are reported as pass or fail. The degree of failure may be light, moderate, or severe.

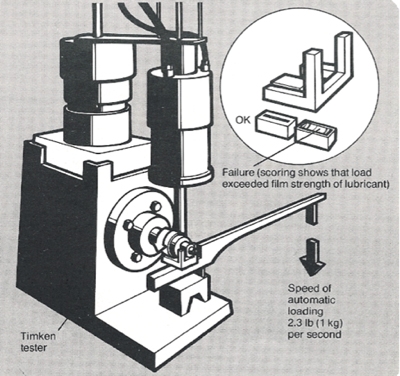

Timken OK Load Test - used to measure the load-supporting capabilities of gear oils. It is run by pressing a steel block against a rotating shaft. The load is measured as the heaviest load that can be applied without scoring the block. A 40-lb. Timken load is an indication of a good extreme pressure oil or grease.

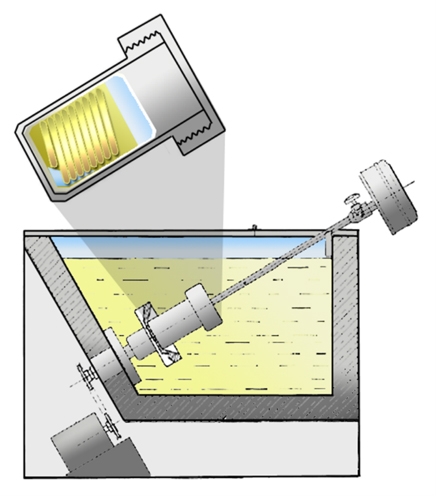

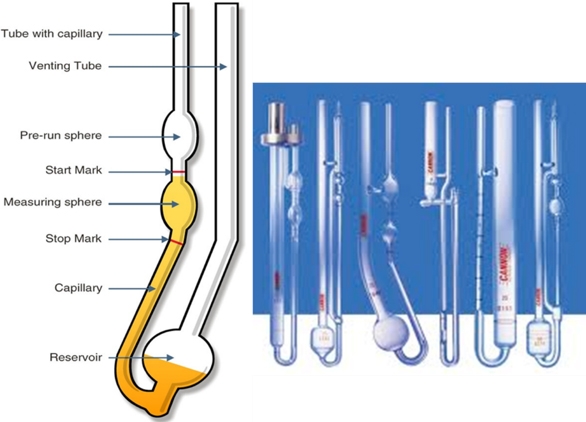

Viscosity - a fluid’s resistance to flow and is the oil’s most important property. Kinematic viscosity is the time required for a fixed amount of oil to flow through a capillary tube under the force of gravity.

Oil is drawn into the tube by suction. Tube is submerged in a constant temperature bath. Temperature is raised to 40 or 100 C. Time for oil to flow from start to stop mark is measured in seconds. Time multiplied by the tube Calibration number (constant).

Kinematic viscosity is expressed in centistokes (cSt) and is usually measured at 40°C for industrial oil and 100°C for engine oils. Saybolt Universal Viscosity, also known as SUS, SSU or SUV is measured as the amount of time required to measure 60 ml through a standard orifice.

Absolute viscosity is the tangential force on a unit area of either one of two parallel planes at a unit distance apart when the space is filled with liquid and one of the planes moves relative to the other with unit velocity in its own plane. It is expressed in Centipoise (cPs).

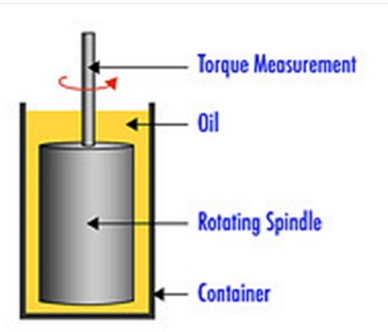

Apparent viscosity is absolute viscosity measured at a given shear rate relating to non-Newtonian fluids (e.g., multigrade motor oils). Absolute viscosity is measured with a rotary viscometer. The Spindle turns in oil reservoir. Torque (resistance) is measured. The viscosity is reported in Centipoise (cPs).

Other tests for expressing viscosity of petroleum fluids under different conditions include Redwood Universal, Redwood Admiralty, Engler, Saybolt, Furol and Brookfield. ASMA and SAE set up their own standards for expressing viscosity. As a reference, an AGMA 5 gear oil is approximately 100 cSt @ 40°C or 500 SSU @ 100°F and is similar to an SAE 90 gear oil and an SAE 50 engine oil.

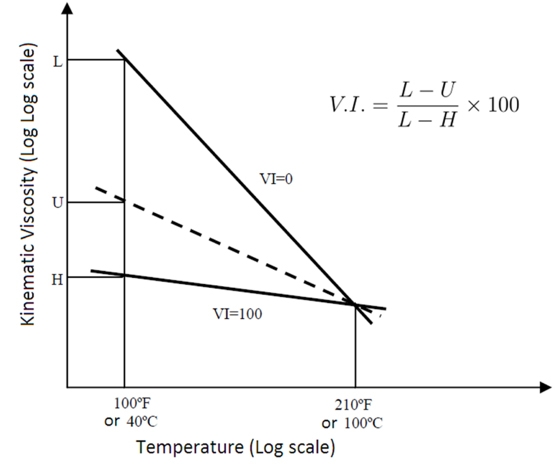

Viscosity Index is an empirical number indicating the rate of change in viscosity of an oil within a given temperature range. It is calculated from viscosities measured at 40°C and 100°C. for the unknown oil: Y = Kinematic viscosity @ 100 C and U = Kinematic viscosity @ 40 C.

You need two reference oils. One with a VI of 100 and one with a VI of 0. Both must have the same viscosity as the unknown oil @ 100 C.

H = Kinematic viscosity @ 40 C of the VI=100 oil

L = Kinematic viscosity @ 40C of the VI=0 oil

The VI of the unknown oil is then:

VI = 100(L-U)/(L-H).

Water Concentration - is measured qualitatively through the use of the crackle test. More accurate measurement is obtained with the Karl Fischer test or distillation tests. Water is the most common contaminant in a steam turbine reservoir.

Water and sediment test are also known as BS&W for Bottom Sediment and Water. It is the measure of the amount of water and sediment accumulated by the oil while in service. The modified test using naphtha indicates water and sediment plus oxidized material.

Water Washout - a method for determining the water washout characteristic of lubrication greases from a bearing under prescribed laboratory conditions and measures the tendency of grease to withstand water washout in bearings. A ball bearing is rotated 600 rpm; 100°F water impinges on the bearing plate. The test measures the percent of grease washed out in one hour. The test is repeated with 175°F water.

Wheel Bearing - is a service evaluation of ball and roller bearing greases. It simulates the conditions of these lubricants in actual operation. It measures the leakage of a lubricant from the hub and shows the tendency of the grease to form varnish-like deposits on the bearing.

Tags: Oil Analysis, Oil Performance, Oil Test, Oil Analysis Test, Oil Analyzing, How To Do Oil Analysis, Oil Sample Testing